The most important purpose of packaging is to protect the material (product). Adopting reasonable packaging can make the materials (products) free from or reduce the damage and influence, so as to achieve the purpose of protecting the products. In order to better promote our company's internationalization strategy, enhance the competitiveness of the company's products and brand image, and further realize the standardization of the packaging of the export project materials, in view of the complexity of the transport mode of the export project materials (products), the number of times of loading and unloading, the long distance of the transport, the long period of storage, the storage conditions of the storage yards and other practical conditions, and in order to ensure the convenience of loading and unloading of the goods of the export project, stacking and storing the goods in the entire transport process and safety, we have prepared the “Goods Packaging”. In order to ensure the convenience of loading, unloading, stacking, storage and other operations during the whole transportation process of export project cargo and safety, we hereby compile the Cargo Packing Manual.

I. Scope of Application

This “Cargo Packing Manual” is applicable to the quality control of packing, lifting, loading and transportation process of steel structure products.

II. Basis of Preparation

1. Packing essentials of each project

2. Packaging requirements of each supply contract

3. Compilation of National Standards on Packaging 3

4. Packaging should be based on the product's external dimensions, structural characteristics, weight, distance, transportation methods (railroads, highways, waterways) and other characteristics, must have sufficient strength to ensure that many handling and loading and unloading, safe and reliable delivery to the destination.

Packaging size and weight requirements

The packing of steel structure should be based on the principle that the steel structure parts can be safely and correctly transported on land and loaded into the cabin safely and correctly, the width of the packing should not be more than 2.6 meters, the height should not be more than 2.8 meters, the length of the steel structure parts should be ≤24m, and the weight of the single bundle packing should be ≤25 tons.

Container transportation should meet the requirements of container size and weight.

Packaging forms and applicable product types

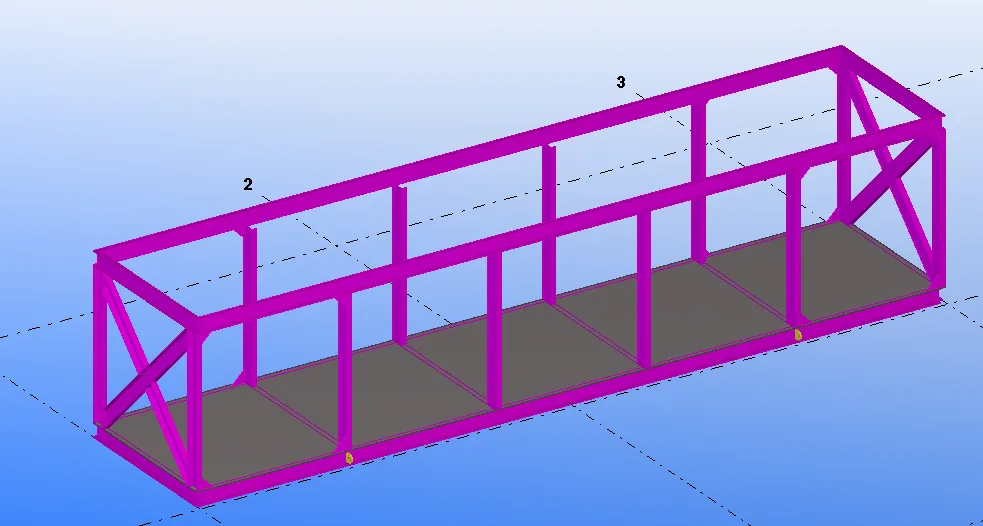

1. Frame packaging

1.1 The external dimensions of the frame: length not more than 12 meters, width not more than 2.6 meters, height not more than 2.8 meters; after loading the goods, the total weight of the goods and the frame should be ≤ 25 tons.

The frame mainly consists of: bottom crossbeam, column, top crossbeam, cross diagonal braces, fascia board, bottom board and lugs, etc. The top crossbeam is to be welded with the top frame beam after the goods (equipment) are loaded into the frame.

1.2 Applicable product types: the frame is suitable for materials that are not pressure-resistant and shaped, such as small steel structures, color steel coils, steel coils, galvanized coils, color steel tiles, sunshine tiles and so on.

Translated with DeepL.com (free version)

Framed package artwork:

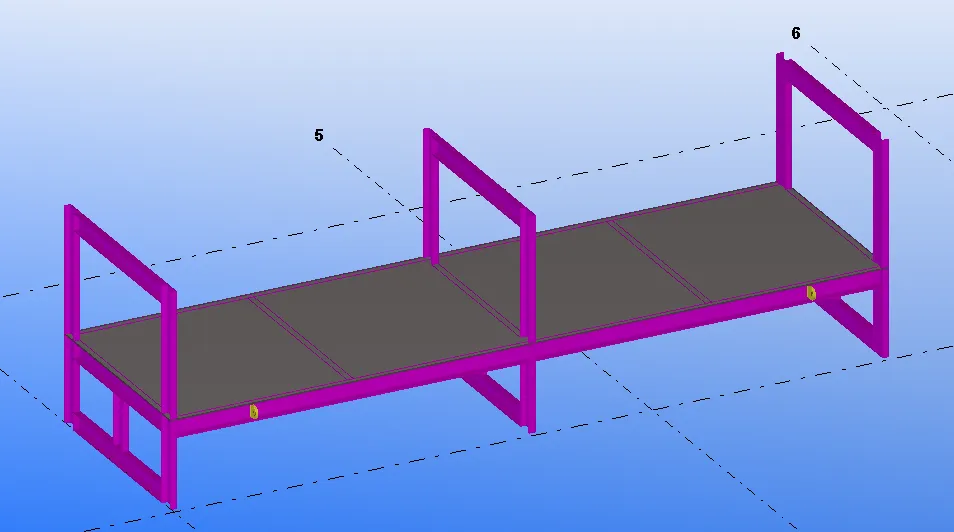

2. “U” frame packaging

2.1 The external dimensions of the frame are as follows: width not more than 2.6 meters, height not more than 2.8 meters; after loading the goods, the total weight of the goods and the frame should be ≤ 25 tons.

The frame mainly consists of: bottom crossbeam and connecting crossbeam, U-frame column and top crossbeam, and lifting lugs.

2.1 Applicable product types: steel columns, steel girders, crane beams, steel supports, purlins and other steel components in large or small bundles.

“U"-shaped rack packing pattern:

3. Tin box packaging

3.1 The external dimensions of the tin box regulations: generally square or rectangular, with the total volume of goods, to have sufficient strength. After loading the goods, the total weight of the goods and the tin box should be ≤ 25 tons.

Tin box mainly consists of: bottom, column and top are made of angle steel or channel steel, I-beam, four sides and upper and lower bottom are welded with steel plate, and four corners are welded with lugs.

3.2 Applicable product type: connecting bolts, nuts, spacers and connecting plates for steel structure parts.

Tin box packing drawing:

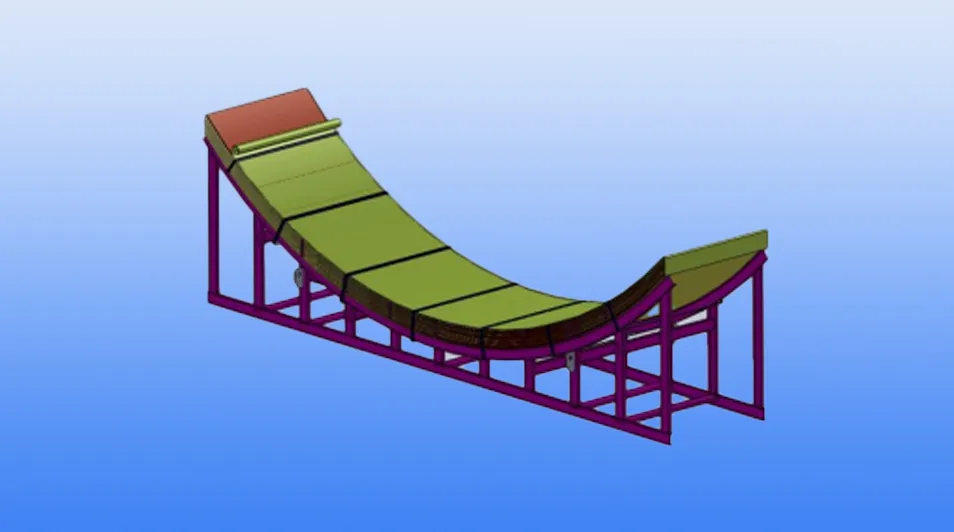

4. Saddle rack packing

4.1 The external dimensions of the saddle rack are as follows: width not more than 2.6 meters, height not more than 2.8 meters, and the length of the packing rack is not less than 2/3 of the length of the curved plate. after loading the goods, the total weight of the goods and the tin box should be ≤ 25 tons.

The saddle rack mainly consists of: top curved beam, bottom beam, column, connecting beam, lifting lugs and fixed block accessories.

4.2 Applicable product type: packaging of curved steel plate; steel plates with different curvature or different bending radius shall not be mixed.

Saddle rack packing pattern:

V. Packaging requirements of goods

1. Goods packaging should ensure that the goods in the entire transport process of loading and unloading, stacking, storage, convenient and safe, according to the characteristics of the goods themselves reasonably designed center point and lifting position, to ensure that the goods are loaded and unloaded many times to ensure that the safety of the damage-free arrival of the project site.

2. Packaging materials should be fixed firmly, without tampering, tipping, loose bundles, stacking deformation of the outer packaging and the phenomenon of cargo damage; packaging internal protection of components, take the necessary measures to prevent possible bending deformation.

3. Packaging dimensions and weight should be in line with the requirements of the limit, for the volume of oversized, overweight, more than the means of transport of goods beyond the limits, should be as far as possible disassembled and dispersed, in order to safe and normal transportation.

4. All packages should be in accordance with the national standard GB/T191-2008 Packaging, storage and transportation of graphic symbols, such as: upward, the location of the lifting point, moisture-proof, rain-proof, shock-proof, corrosion-resistant and other markings.

5. The packing list shall be filled in according to the buyer's requirements, the electronic version shall be sent to the buyer's mailbox, and the paper version of the delivery note and the list of freight shipments shall be carried and delivered by the freight driver.

6. Marks should be filled in the maximum dimensions of the packaged goods (including lugs), the error should be within the range of ± 50mm. Distributed to the terminal of the goods its mark, packing list, delivery note on the name, model, brand, etc. should be consistent with the name of the physical, model, brand, origin, etc. must be in line with the contract requirements.

Marked drawings: