Sanjian Meichen provides

users with one-stop

steel structure

customization services

We have a professional team of steel structure designers to provide users with one-stop customized services, which can better meet the personalized needs of customers and ensure the applicability and practicality of the products.

We strictly follow international green environmental protection standards in material selection, and provide users with high-quality steel structure products through advanced technology and strict quality inspection processes.

We have a professional installation team to ensure the accurate installation and smooth progress of steel structure products, which not only saves customers' time and energy, but also improves the overall quality and efficiency of the project.

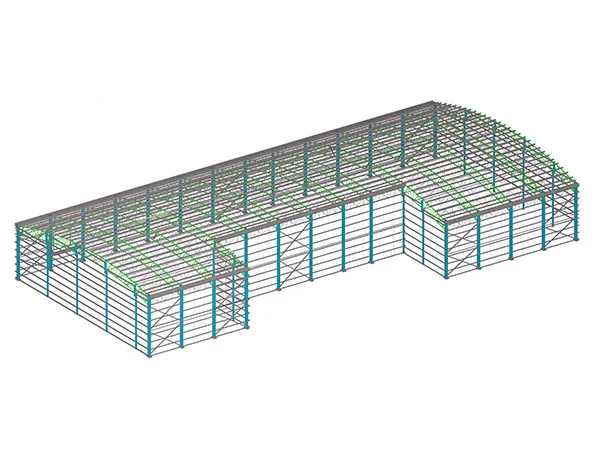

A steel structure is a type of construction that utilizes steel as the primary material for the structural framework. It is characterized by the use of steel elements such as beams, columns, trusses, and other components that are fabricated and assembled to create the load-bearing skeleton of a building or other types of structures. Steel structures are known for their strength, durability, and versatility, making them a popular choice in modern construction for a wide range of applications.

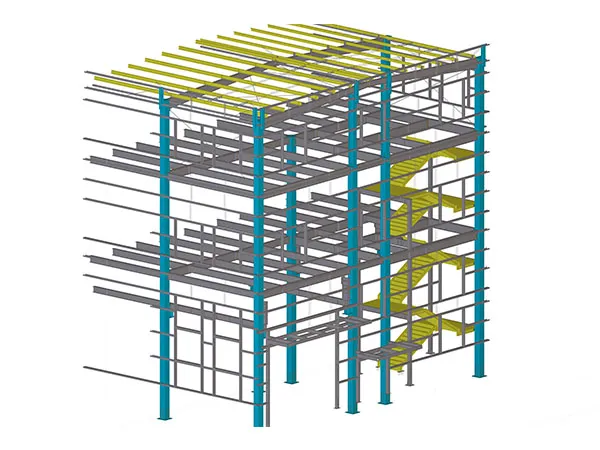

Office Building Steel Structure Project

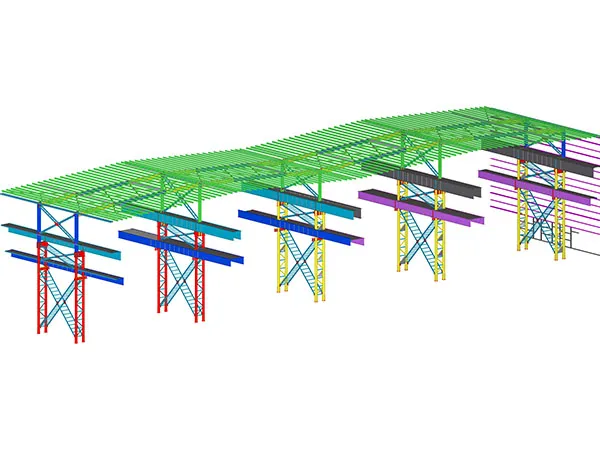

Shield Machine Steel Structure Workshop Project

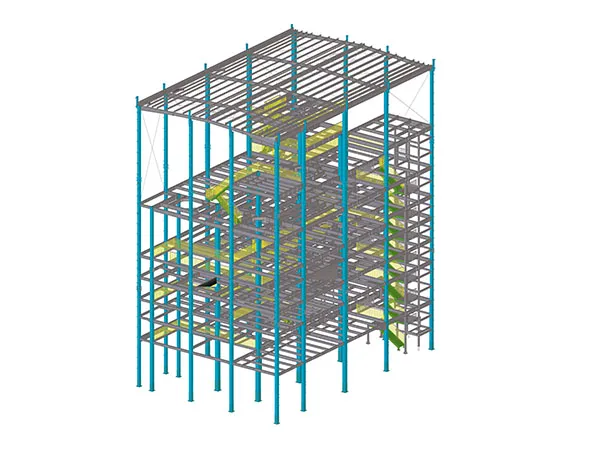

Shengmante Multi-storey Factory

China Science and Technology Engineering

Hot and Sour Noodle Steel Structure Project

Shenyu Steel Structure Project

Yard

Hongxing Petrochemical

Hongxing Engineering

Yard Shed Project

Ruichang Petrochemical

Hangzhou Automobile Project

CNC cutting and beveling of plates

U-type assembly machine

Inner partition welding

Inner partition welding

Box type submerged arc automatic welding

Flame straightening of box beams and columns

Parts assembly welding

Shot blasting machine rust removal

Spray paint

CNC cutting of plates

H-type Assembly machine assembly

Submerged arc automatic welding

Straightening machine straightens flange

Assembly welding

Shot blasting machine rust removal

Spray paint

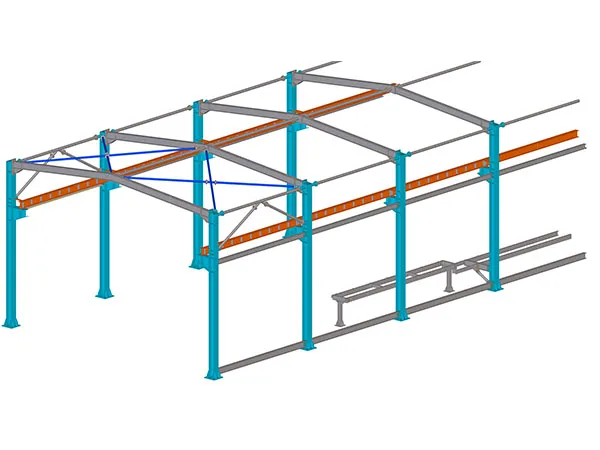

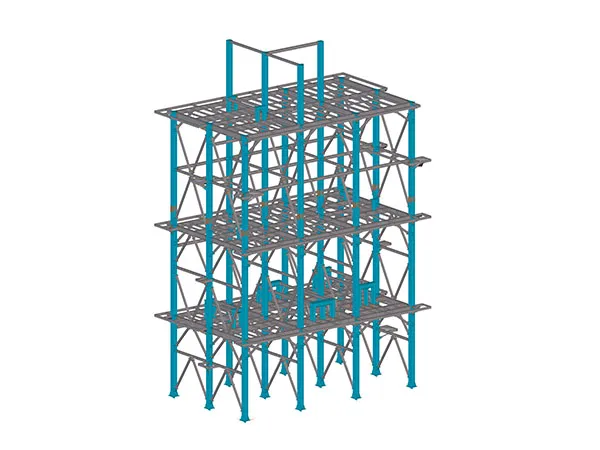

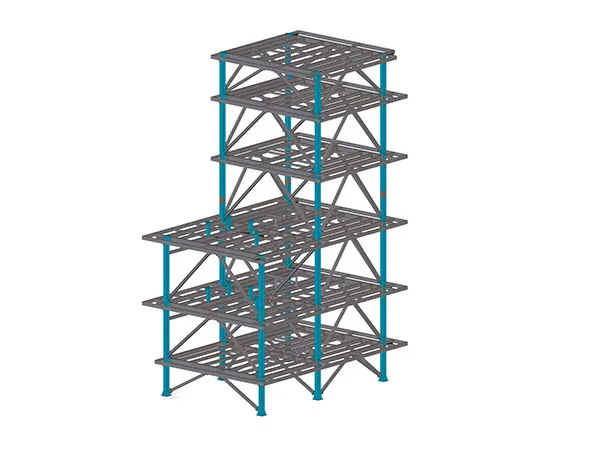

Industrial steel structures are the backbone of modern manufacturing and warehousing facilities. These structures are renowned for their strength, durability, and versatility, making them ideal for a variety of industrial applications. They are designed to withstand the rigors of heavy machinery, large loads, and the demanding conditions often present in industrial settings.

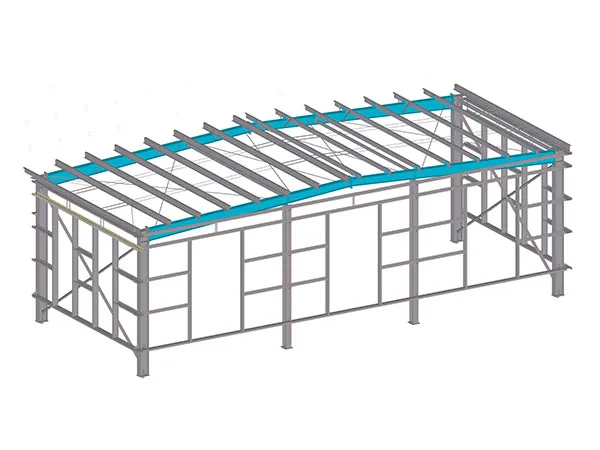

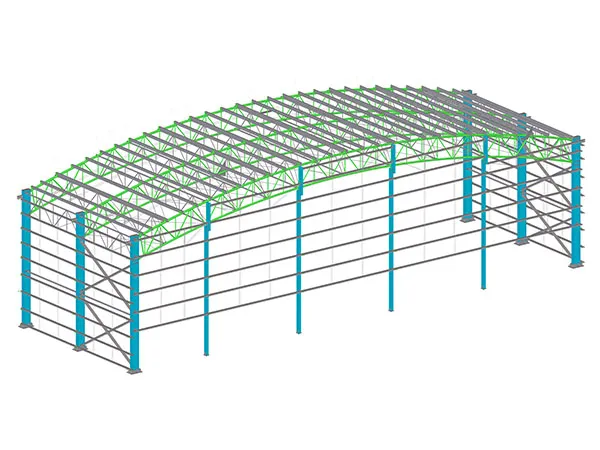

Agricultural steel structures are the epitome of functionality and resilience in the agricultural sector. These structures are specifically designed to withstand the unique challenges posed by the natural environment and the demands of modern farming practices. They offer a range of benefits that make them an ideal choice for a variety of agricultural applications, from barns and silos to storage facilities and livestock shelters.

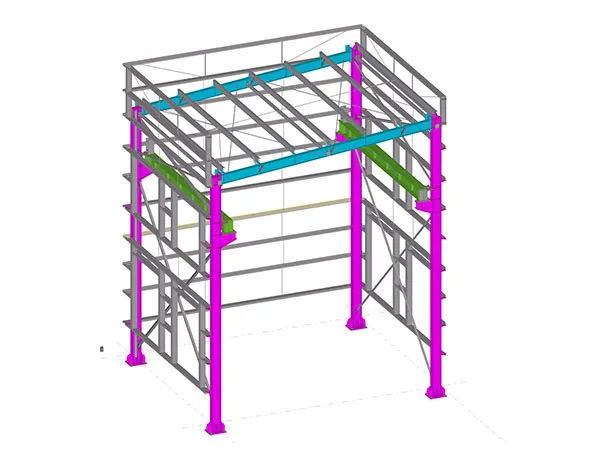

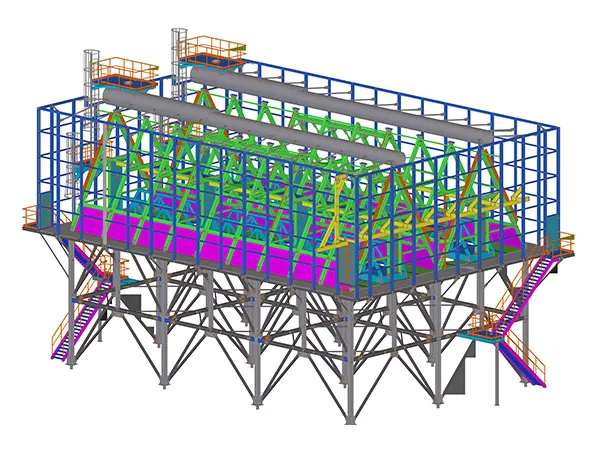

Metallurgical steel structures are specifically designed to meet the rigorous demands of the metallurgical industry, which often involves extreme conditions such as high temperatures, heavy loads, and corrosive environments. These structures play a critical role in various processes like smelting, refining, and the production of metals.

Meichen Steel Structure Delivery

Steel structure Installation Detail Display

Steel Structure Workshop Construction Show

Steel Structure Shed Installation

The Role of Steel Structural Wind Columns

Steel Structure Lifting Detail Display

How Steel Villas Are Built

Primary Secondary The Difference Between Steel Structures

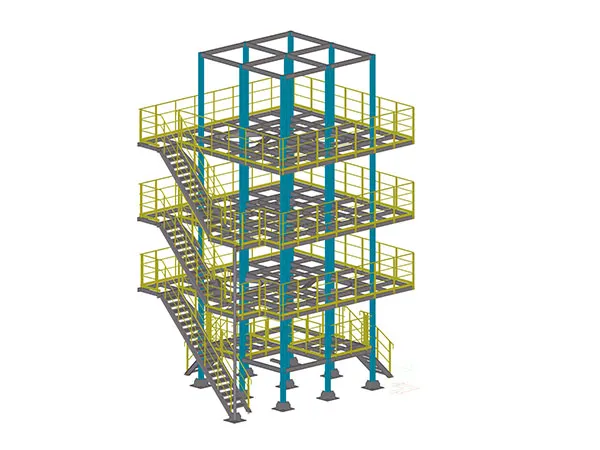

Before installation, a detailed design and site-specific erection plan must be in place. This includes understanding the construction sequence, which is crucial for the safe and efficient assembly of the steel structure.

The foundation must be properly prepared and leveled to support the weight of the steel structure and the equipment used during construction. It's essential to ensure that the foundation can handle the load and is stable.

All steel materials must be thoroughly inspected according to quality standards and certificates of origin. This is especially important for structural bolts and anchor bolts, which are critical for connecting the structure's component.

Safety is paramount during steel structure installation. Workers must be equipped with personal protective equipment (PPE), and safety nets should be in place. Clear safety signs and instructions should be provided, and workers should be trained on safety regulations.

All equipment, including cranes and forklifts, must be inspected before use. This ensures that they are in good working condition and reduces the risk of accidents during the lifting and moving of heavy steel components.

The tightening force of bolts is crucial for the stability and safety of the structure. Specialized tools should be used to check the tightening force, and adjustments should be made as necessary.

Precision in the alignment and leveling of steel components is essential. High-precision measuring tools and modern technology, such as laser alignment systems, can be used to ensure accuracy.

Continuous supervision and inspection are necessary throughout the installation process. This includes checking the quality of connections, alignment, and structural integrity to ensure that all construction activities follow design specs and standards.

Only qualified persons with recognized knowledge, skills, or experience should conduct steel erection. Special training programs may be required for workers involved in multiple-lift rigging operations and connector procedures.

Environmental conditions such as temperature and humidity can affect the installation process, particularly the tightening force of bolts. These factors should be taken into account during the installation.

Compliance with regulatory standards is mandatory. In the United States, this includes adherence to OSHA’s Construction Standards, particularly Subpart R, which covers regulations for steel erection.